Advanced Additive Manufacturing

of User-Focused Facial

Prostheses with Real-Life

Colour Appearance

Advanced Additive Manufacturing of User-Focused Facial Prostheses with Real-Life Colour Appearance

Facial prostheses are needed when patients are treated for certain cancers or injuries affecting the nose, lips, eyes, ears, or skin. The quality of these prostheses is important to protect the affected area and give patients confidence, self-esteem, and an improved quality of life.

The demand for prostheses is growing as the population ages and cancer rates increase. In the UK, about 2,500 new patients need facial prostheses each year, and the prostheses then need to be replaced every 12-18 months as they degrade and discolour.

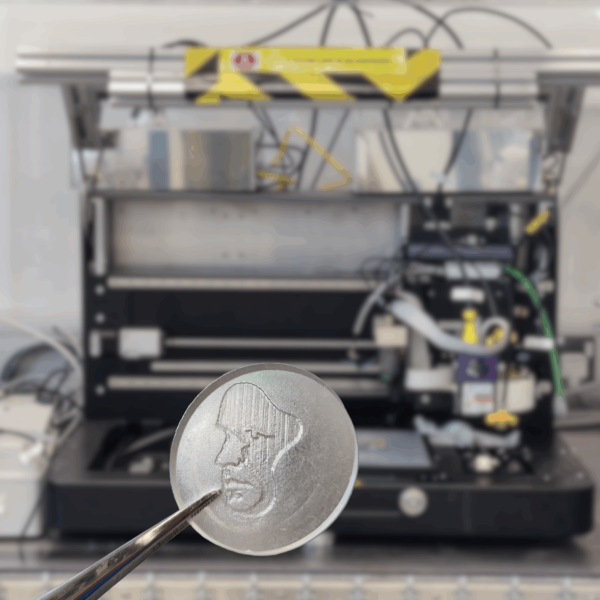

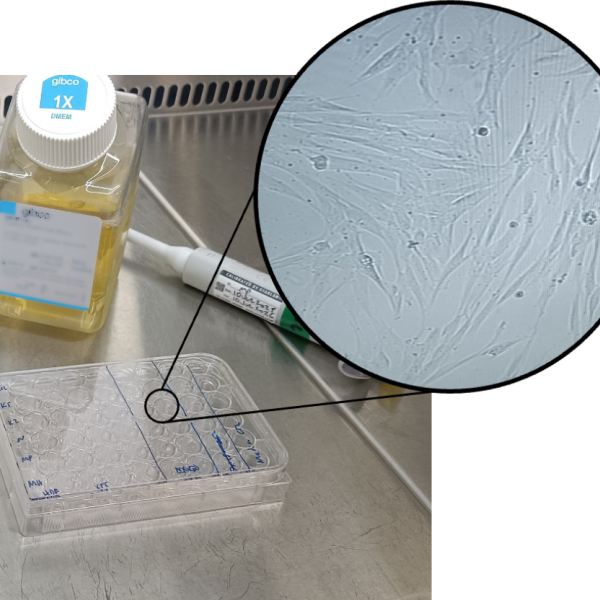

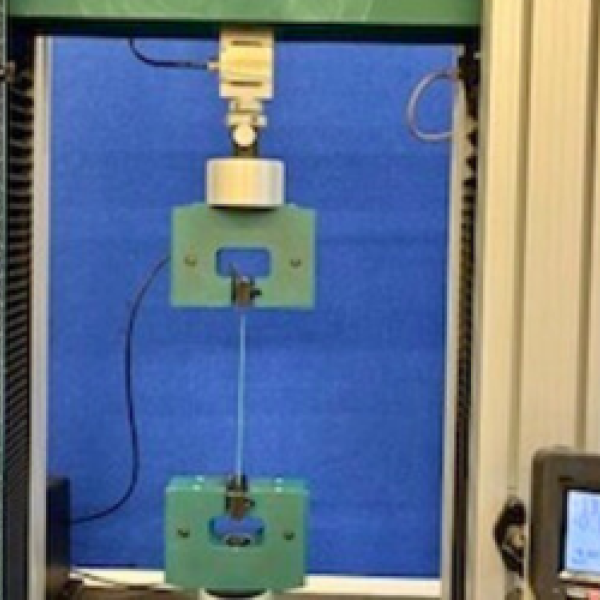

New ways of imaging and computer modelling 3D skin appearance are needed, new combinations of medical grade silicones and pigments, and new digital methods of manufacture that can produce prostheses with the required softness, colour, texture, and fidelity. AMFaces will address these challenges.

Producing facial prostheses is currently slow and technically difficult, depending on a few highly experienced maxillofacial prosthetists, many of whom will be retiring in the near future. Yet developing a new way of delivering high-quality prostheses is difficult.

Facial prostheses are needed when patients are treated for certain cancers or injuries affecting the nose, lips, eyes, ears, or skin. Quality prostheses give patients confidence, self-esteem, and an improved quality of life.

The demand for prostheses is growing as the population ages and cancer rates increase. In the UK, about 2,500 new patients need facial prostheses each year, which then need to be replaced every 12-18 months as they degrade.

Producing facial prostheses is slow and complex, relying on a few highly experienced maxillofacial prosthetists. A new way of delivering high-quality prostheses needs a multidisciplinary approach.

AMFaces is developing new ways of imaging and computer modelling skin, new combinations of silicones and pigments, and new digital manufacturing methods producing the required softness, colour and texture.

Research vision

This project will enable bespoke ultra-realistic facial prostheses to be developed for individuals affected by cancer, trauma, and congenital defects. It will deliver a new approach to manufacture on demand and improve the quality of life for thousands of patients in the UK and beyond.

Approach to research

The project has brought together experts and early career researchers from four UK universities. The team comprises clinicians in maxillofacial and oral surgery and scientists and engineers in additive manufacturing (3D printing), reconstructive science, biomaterials, colour science, and imaging. Our approach at every stage is patient centred.

Project outcomes

Working with two NHS Foundation Trusts (Manchester University FT and Guy’s and St Thomas’ FT, London), this research will support regional NHS networks for prosthetic services and charities. We will work with small and medium enterprises to develop sustainable research and further investment. We will share our technological innovations with the clinical, scientific, and engineering communities, and especially with developing countries.